[sharelines]Reformed CAFE standards should include diesel’s clean potential in emissions regulations.

Are diesel engines part of the problem or part of the solution?

What is the truth about diesel engines? Are they inherently dirty? Do they belch clouds of black soot? Are they unsuited to cars, as evidenced by 1980s class-action suits against GM’s diesel “lemons?” Do they make an unnecessary racket when idling and accelerating? Are their emissions toxic and a threat to human health? Many ask, in this age of ultra-clean transport, why do we still have diesel engines? The governor of Tokyo and air quality regulators in southern California have both launched campaigns to ban them.

But there’s another side to the story of diesel engines. European regulators assert they are an answer to climate-change threats. Many automotive companies claim that new diesel engines are dramatically improved and as clean and quiet as gasoline engines. And freight companies rely almost exclusively on diesel engines for their trucks because they are durable and efficient. Indeed, diesel engines continue to increase their market share worldwide, now accounting for about forty percent of all roadway fuel consumed.

Because government plays a central role in determining diesel’s destiny, a broad and sound understanding of diesel engines is especially important. Here, we offer a synthesis of the issues and conflicts surrounding diesel technology. We look at technical, regulatory, and economic issues addressing trucks, buses, and cars. We note that diesel engine technology is evolving rapidly. While we find their future attributes and health impacts are still uncertain and that a definitive assessment is not yet possible, we find ourselves cautiously optimistic.

Diesel History and Status

Diesel engines have come to play major roles in our freight transport system. They have powered almost all heavy-duty trucks and most transit buses for decades, for good reasons. They are more fuel efficient, durable, and reliable than gasoline engines; they require less maintenance, provide high torque for moving heavy loads, and, in high-mileage vehicles, tend to have lower lifecycle costs. The cost advantage is especially crucial to the freight industry. Indeed, until the tightening of heavy-duty engine emission standards in the late 1980s, diesel engine use in trucks and buses was accepted as unquestionably positive. Even now, despite growing controversy about their health effects, diesel engines continue to gain prominence. They doubled their share of total roadway fuel use in the world in the past 25 years, and the percentage continues to increase.

Diesel engine use has been most controversial in the United States. Mercedes had been producing diesel cars for many years, but in the mid-1970s, in response to skyrocketing fuel prices and newly imposed fuel-economy standards, a number of other manufacturers began producing diesel cars. Market penetration increased to 6.1 percent of light-duty vehicle sales by 1981. But one manufacturer was too quick getting to market. One of the GM diesel car engines, a 5.7-liter engine converted from truck use, turned out to have many widely reported problems (though it is instructive that other diesel engines in GM cars performed well). GM spent large amounts of money vainly trying to fix the engine, settling class- action lawsuits, and dealing with complaints to the Federal Trade Commission.

The California Air Resources Board proclaims this will be the “decade of the clean diesel.”

Because of that bad experience, and also because diesel fuel prices in the US increased around that time to rough parity with gasoline prices and have remained at that level, no automaker has aggressively promoted diesel cars since. A recent resurgence of interest in light-duty diesels reflects steady improvements in noise and emissions and automakers’ difficulty meeting the national 20.7 mpg fuel economy standard for gasoline-fueled light-duty trucks (applicable to vans, pickups, and sport utility vehicles). Diesel engines are now being introduced in small numbers in pickups and other light-duty trucks. Diesels account for 0.1 percent of automobile sales (with VW the only supplier) and approximately 4 percent of light-truck sales in the US.

The contrast with Europe is striking. There, diesel cars now account for over thirty percent of sales—over fifty percent in some countries—and the percentage continues to climb. Aided by low diesel-fuel prices, relatively gentle regulatory treatment of diesel car emissions, and aggressive CO2 emission goals, diesel cars are likely to exceed forty percent of European vehicle sales within a decade.

Trucks and Bus Emissions—Past and Present

Diesel engines produce much lower levels of carbon monoxide (CO) and hydrocarbons (HC) than do gasoline engines, but much higher levels of nitrogen oxides (NOx) and particulate matter. Unfortunately for diesels, their low emissions of CO and HC are no longer a strong attraction in the US. As a result of aggressive controls placed on gasoline engines (and other stationary sources), total carbon monoxide and hydrocarbon emissions have already been greatly reduced in the US and are no longer of principal concern. The most problematic air pollutants are now considered to be NOx, which combine with hydrocarbons to produce smog (ozone), and particulate matter—small carbon particles that contribute to respiratory problems and cancer.

In the US, diesel engines contribute about a third of the nitrogen oxides produced by vehicles (vehicular emissions account for about half of all urban NO x). They contribute a smaller share of particulate matter, but because vehicles tend to emit fumes closer to humans than other sources, and to produce relatively more of the dangerous nano-scale size particles, they are subjected to more intense regulatory scrutiny. NOx emission rates from modern diesel engines are about five to ten times greater than from comparable gasoline engines, and particulate emissions are ten to three hundred times greater. Diesel engines are now a principal focus among air quality regulators. The California Air Resources Board proclaims this will be the “decade of the clean diesel.”

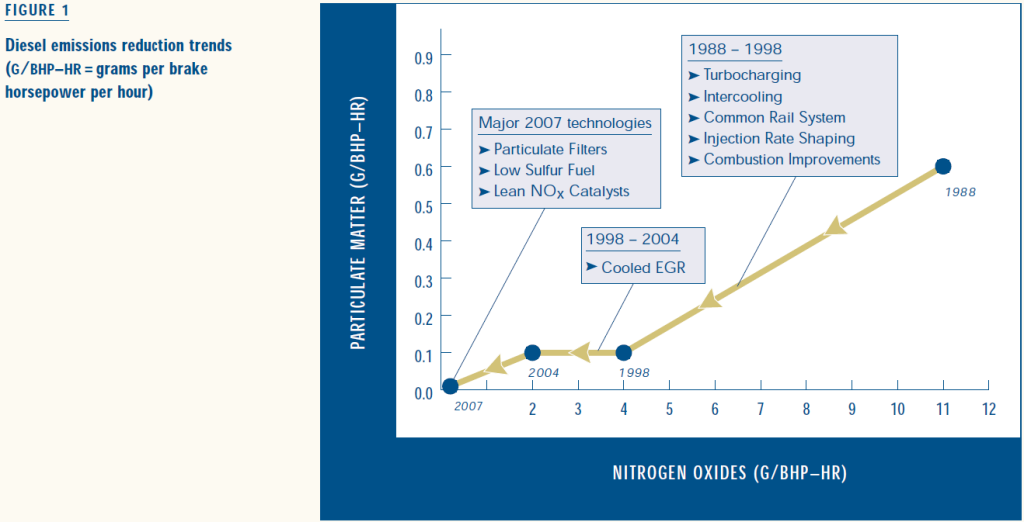

Vehicular emission controls were first imposed in the 1960s on gasoline engines, with increasingly stringent standards since. Diesel truck and bus emissions, in contrast, were essentially unregulated until the early 1990s. Lax treatment was due to the difficulty of creating standardized rules for trucks operating with varying loads and in widely disparate applications. Regulators recognized that the relatively small diesel engine manufacturers had limited resources, and that the trucking lobby was politically powerful. As indicated in Figure 1, the first set of stringent heavy-duty diesel particulate matter standards took effect in 1994, and more stringent NOx standards followed in 1998. As with gasoline engines, initial emission improvements were easy and inexpensive. New 1998 diesel engines produced over eighty percent less particulate emissions and sixty percent less NOx than older engines (largely using technology from Europe). Future emission reductions will be far more difficult, in part because catalysts and other emissions-control devices developed for gasoline engines are not transferable to diesels. Considerable effort is now being devoted to developing new diesel-specific technologies.

Diesel emission reduction is hindered by the “diesel dilemma.” Changes to reduce NOx emissions increase particulate emissions, and vice versa: high temperatures and additional oxygen reduce particulate levels, but increase NOx formation. A similar trade-off exists between NOx and fuel economy: adjusting the engine for greater economy results in higher NO x. The challenge for engine manufacturers is to reduce both NOx and particulates, and retain diesel’s superior fuel efficiency.

Regulators in California, US, Europe, and Japan all continue to tighten heavy-duty truck emission standards. US regulators are requiring that emissions of both pollutants be 98 percent below 1988 levels by 2007. In parallel, European regulators are about to require use of particle filters by 2005 and NOx catalysts by 2008. Manufacturers are on track to achieve the huge reductions in particulates being called for. Large reductions are also being made in NOx emissions, but not nearly as fast nor as easily. NOx control on diesel engines continues to lag behind gasoline engines by over a decade.

Car Emissions

The steep learning curve also applies to light-duty diesel emissions, though circumstances are quite different. In the US, diesel cars must meet the same stringent pollutant emission standards as gasoline cars. A few companies have technology that gets them close to the national standard (which is good enough since they are allowed limited averaging to meet an overall fleet average). But none qualify for even the least stringent category in California, where standards are somewhat more rigorous, and thus no light-duty diesels are being sold in that state. It is uncertain whether any manufacturer will be able to meet federal standards in 2004, when they are next tightened.

The European situation is quite different. Europe treats diesel car emissions more leniently. While Europe has been closing the gap in gasoline emission standards with the US and California over the past decade, this has not been so with diesel cars. Europe continues to impose considerably weaker NOx and particulate-matter standards on light-duty diesel vehicles. The test cycles are different, so exact comparisons are not possible, but the European standards are less stringent by at least a factor of six (i.e., the US Tier II and California ULEV standard in 2004 will be 0.043 grams/ km for NOx and the California SULEV standard will be 0.012, while the comparable European standard for diesel cars will be 0.25 grams/ km). Moreover, the European standard covers only the first 100,000 km of a vehicle’s life, while the US and California standards are for 193,000 km. Similar differences exist for particulate standards.

Japan also treats diesel cars more lightly than the US. But diesel cars in Japan have not enjoyed the same market success as in Europe. Diesels slowly increased to ten percent of total cars on the road in the 1990s, but then began to recede at the end of the decade. The principal reason for this slower diesel growth in Japan appears to be a sense that diesels are a principal source of persistent air pollution. In 1999, the Governor of Tokyo proposed to ban the sale and use of diesel vehicles in the entire city. While that will not happen, a retrofit program may emerge instead. In any case, it indicates the extent of antagonism to diesels. In addition there have been court cases where the public has sued the government and toll-road authorities, claiming that vehicle pollution, especially from diesels, is damaging health. The effect seems to be a chilling of diesel car sales.

The Future of Diesel Emissions

Black clouds of soot are about to recede into history, certainly with new vehicles. Today’s diesel engines burn far cleaner. Emission improvements to date have mostly involved improved engine design and operation, including electronic engine controls, fuel injection, and the shaping of the fuel pulse as it enters the cylinder—as opposed to after-treatment technologies, such as catalysts and filters, that reduce emissions after they leave the engine.

But even with those improvements, diesel NOx emissions remain a large share of total national emissions of NO x, and particulate emissions continue to be a serious health hazard. After-treatment technology, widely used on gasoline engines for over two decades, will soon be applied to diesel engines. The 2004 heavy-duty standard for NOx will be largely met with a new after-treatment technology called cooled exhaust gas recirculation (EGR), which has also been extensively used for gasoline engines. EGR lowers the temperature of the combusting fuel by recirculating oxygen-depleted exhaust gases back to the cylinders, thereby reducing the oxygen content of air involved in the burn. Cooled EGR will need to be supplemented or replaced by other technologies to meet the stringent heavy-duty NO x standards of 2007.

Black clouds of soot are about to recede into history. Today’s diesel engines burn cleaner.

To meet the 2007 standards, a sophisticated multi-pronged systems approach will be needed, encompassing three technologies: fuel changes, engine controls, and after-treatment. Likely changes include the use of low-sulfur fuel, oxidation catalysts, selective catalytic reduction (SCR) techniques, and particulate filters.

Dramatic emission improvements are likely to continue. But improvements may not be as fast or as large as required by the standards. Some of the challenges and questions that underlie anticipated improvements include the following:

Sulfur removal from fuel. Sulfur, which occurs naturally in petroleum, poisons catalysts and particulate filters and produces particulates. It must be removed, but doing so is costly and difficult. The oil industry prefers a slow phase-down. Only one control technology, selective catalytic reaction (SCR), can function with high sulfur fuel, but SCR has other drawbacks. Many European countries, such as Sweden, already require fuels to be low in sulfur, and some refiners already supply very low sulfur fuels. The US EPA has proposed a ninety percent reduction in sulfur content of diesel fuel, to less than 15 ppm, by 2006, but it is being contested.

Emission Control Performance. It took more than a decade for reliable two-way gasoline catalysts to evolve into effective and durable vehicle components. Many didn’t perform effectively as they aged, and others degraded engine performance. Tampering, malfunctions, and poor maintenance were parts of the problem. The same will hold for new diesel control technologies and engine designs. Particle filters are of some concern because they cause increased backpressure, which limits the flow of fuel, reducing fuel economy and possibly damaging the engine. Catalytic systems are of uncertain and unproven durability and reliability. SCR systems are problematic because drivers must load another fuel (urea); without urea, emissions will not be reduced, and with an incorrect fuel, the catalyst is ruined.

As with gasoline cars, the net effect of tampering, malfunctions, and poor maintenance is much higher emissions. One study estimated that over  its life, a 1995 truck’s average emissions increase by 34 percent for HC, 7 percent for NO x, and 44 percent for particulates. Another (Northern Front Range Air Quality Study) found actual in-use particulate emissions from heavy-duty trucks to be 20 to 170 percent higher than predicted by EPA models, and NOx emissions to be 20 to 100 percent higher. Inspection and maintenance programs and onboard diagnostic technology are possible solutions, but they have not yet proven to be highly effective (with either gasoline or diesel engines).

its life, a 1995 truck’s average emissions increase by 34 percent for HC, 7 percent for NO x, and 44 percent for particulates. Another (Northern Front Range Air Quality Study) found actual in-use particulate emissions from heavy-duty trucks to be 20 to 170 percent higher than predicted by EPA models, and NOx emissions to be 20 to 100 percent higher. Inspection and maintenance programs and onboard diagnostic technology are possible solutions, but they have not yet proven to be highly effective (with either gasoline or diesel engines).

Particle mass versus number. The design of current regulations may be misguided. Current regulations address the mass of emissions. Thus, emission control strategies are aimed at reducing the total mass of particles. But to accomplish that goal, they tend to produce many more very tiny particles. New health research suggests that nanoscale-size particles are far more dangerous than larger, heavier particles, since the tiny particles navigate past the body’s normal barriers and penetrate deep into the lungs and bloodstream. It may be that modern diesel engines, while producing lower mass emissions (cleaner to the eye), are more dangerous to health. There is evidence that natural gas engines, which regulators are promoting as a substitute for diesels (and sometimes mandating, as with buses in Delhi, India), produce even more very fine particles than next-generation diesel engines. Regulators are exploring new standards that are based on particle size, as a complement or substitute for mass-based standards. The health effects research is not definitive, however, and standards take many years to be altered. The relative importance of particle number versus particle characteristics will influence the type of technologies and strategies adopted. These considerations will be very important for particulate filter retrofit programs, especially since diesel engines typically have a significantly longer life than gasoline engines.

Even if health research were definitive, measurement of small particles is difficult. The size and chemical composition of emissions particles are highly sensitive to a variety of factors— including temperature, sampling technique, and time lags between formation and sampling—making it difficult to characterize and measure these particles. Measurement techniques need refinement to ensure accurate representation of the emissions and to understand their effects on human health.

In summary, dramatic improvements are being made, and the sophistication and effectiveness of diesel emission control is on a steep upward curve. Attainment of heavy-duty 2007 standards is not assured, at least by 2007; but regulators in Europe, the US, and Japan continue to press for major improvements. Industrial R&D investment is scaling up in response to increasingly stringent standards.

Energy Efficiency and CO2 Emissions

Diesel engines are more energy efficient than other internal combustion engines. Advanced direct-injection diesel engines are up to 45 percent more efficient than current gasoline engines, and about 20 percent more efficient than advanced gasoline engines.

The higher energy efficiency is a strong attraction where diesel fuel prices are lower than gasoline prices, and where vehicle manufacturers are subject to fuel economy or CO2 restrictions. No country imposes fuel economy standards on large trucks, nor plans to. Light-duty vehicles are a different story. The US and Japan impose fuel economy standards on cars and light trucks, and the European Union has a voluntary agreement with automakers to reduce CO2 emissions by 25 percent (per vehicle kilometer) between 1995 and 2008. The effect of these policy instruments is to encourage diesel over gasoline. In the US, the effect is muted by lingering memories of the GM diesel car experience and the absence of diesel fuel price advantages. In Europe, however, diesel’s strong price advantage and the aggressive CO2 targets have been highly effective at stimulating diesel car sales.

Economic Consequences

Regulator decisions about air pollutant emissions, greenhouse gases, and fuel economy play an instrumental role in the future of diesel engines and fuels and the success and even survival of many car, truck, and oil companies. Those policy decisions are seldom based on solid scientific evidence. The problem is the proprietary nature of engine and catalyst design and the adversarial nature of many regulator-industry relations. It is difficult to determine the actual state of diesel technologies or to know what levels of regulation are appropriate. Without performance and cost projections, regulators cannot determine how their policies will affect industry. Thus, they engage in a game of chicken, enacting technology-forcing regulations that they hope will not impose undue economic burdens on manufacturers.

In the US, proposed light-duty diesel vehicle standards are so strict that the economic consequences of meeting the standards could prove prohibitive. Anticipating these new and more stringent standards, most automakers have withheld the introduction of diesel engines in cars and light trucks.

The heavy-duty vehicle market will remain loyal to diesel fuels in almost any scenario, but major changes are possible. Some heavy-duty diesel vehicles, including many buses, have switched to natural gas. But even natural-gas trucks and buses will have to reduce their particulate and NOx emissions by a factor of five or ten to meet the very stringent 2007 standards. In the US, where more than 90 percent of all freight is moved by diesel power and where diesel fuel accounts for 25 percent of fuel sold, the economic repercussions of stringent diesel emissions standards could be large and far-reaching.

Health Risks

Central to the debate over diesels is the unresolved question of health effects of particulate emissions. It’s unresolved for several reasons: it’s difficult to tease out the effects of diesel emissions from those of tobacco, other fossil fuels, and other sources; few humans are exposed for an extended time to diesel fumes; and extrapolation of findings from animals to humans is dubious, partly due to species-specific responses. For example, prolonged diesel exposure does not produce lung tumors in hamsters, whereas it clearly does in rats.

Despite these uncertainties, some conclusions can be drawn from the large numbers of studies that have been conducted:

- Fine particles are associated with increased hospital admissions and emergency room visits, asthma, chronic bronchitis, decreased lung function, and premature death.

- Diesel particles have many chemicals adsorbed onto their surfaces, including some known or suspected mutagens and The risk of lung cancer among workers with high exposure to diesel exhaust is approximately 1.2 to 1.5 times the risk in those unexposed.

- Exact biological mechanisms are poorly understood, but small particles (those in the submicron range) are believed to pose the most severe health By number, the vast majority of diesel particulates (92 percent) are less than one micron in diameter. Particles this size can be inhaled and trapped into the bronchial and alveolar regions of the lung.

The overall impact on human health is less clear. Effects range from increased rate of death from cardiovascular and respiratory illnesses (asthma, chronic bronchitis) to cancer. In California, the Multiple Air Toxics Exposure Study found that approximately seventy percent of all cancer risk in the South Coast Air Basin related to outdoor air pollution is attributable to diesel particles—but it also estimates that outdoor toxic air pollution overall accounts for less than one percent of cancer when all risk factors are considered.

The regulatory communities’ interpretations of these results differ. Diesel exhaust includes over forty substances listed by the EPA as hazardous air pollutants, and by the California Air Resources Board (CARB) as toxic air contaminants. In 1998, CARB classified diesel particulate matter itself as a toxic air contaminant. However, the EPA recently acknowledged the uncertainty inherent in the existing studies and recommended not adopting a cancer risk estimate. CARB, on the other hand, has established risk estimates for cancer from diesel exhaust particles.

Complicating the interpretation of health-effects research is the fact that current data do not apply to future vehicles. Because of improvements in engine design and emissions control technology and the use of reformulated diesel fuels, future human exposure will differ from past and current exposures. Secondly, as indicated in Figure 1, future technologies will produce substantially lower emissions, with different characteristics, both chemical and physical. Third, diesel emissions are chemically transformed over time as they move through the air—altering the toxic, mutagenic, and carcinogenic properties of the original emissions. Consequently, the new pollutants from diesels will likely lead to new end products with undetermined levels of hazard.

Based on the above evidence, the Health Effects Institute, a respected independent center jointly funded by car companies and the US Environmental Protection Agency, concludes, “The characterization of modern-day diesel exhaust can not be…used reliably to project future emissions profiles.”

The Long-term Future of the Diesel Engine

Emissions control strategies have evolved from engine design and management to use of after-treatment devices. The goal is to reduce emissions without degrading fuel economy and engine performance. Beyond 2007, the focus will broaden beyond narrow emission control strategies into broader strategies that reduce emissions and enhance other vehicle attributes, including performance and energy efficiency. This broader approach is motivated initially by opportunities to reduce losses and costs associated with idling and stop-and-go operations—not only emissions, but also the large consumption of energy and accelerated wear and tear on the engine. Two strategies already being examined are auxiliary power sources and hybrid drivetrains. As indicated below, these two strategies have the potential to provide not only environmental benefits, but also economic and performance benefits; and they could provide a path toward fundamentally superior designs.

Auxiliary Power Units (APU)

Long-haul heavy-duty trucks in the US idle up to ten hours each day, and as much as fifty percent of total engine run time. Idling consumes significant amounts of diesel fuel and generates large amounts of noise, vibration, and air pollution. Up to a third of NOx emissions is produced by these trucks during idle. Energy consumption is also large, and engine efficiency is very poor. At idle, heavy-duty diesel engines operate at  only one to eleven percent energy efficiency, compared with forty percent efficiency when the engine is operating on the road. Conservative estimates are that a diesel engine in an average late-model truck, idling six hours per day 303 days per year, consumes 1818 gallons of fuel per year. The annual cost of this idling is over $3,000 for fuel, plus more for additional preventative maintenance and engine overhauls. The DOE’s Office of Heavy-Duty Technologies estimates that the total cost of idling heavy-duty trucks in the US is $1.17 billion for fuel and $1 billion for extra maintenance.

only one to eleven percent energy efficiency, compared with forty percent efficiency when the engine is operating on the road. Conservative estimates are that a diesel engine in an average late-model truck, idling six hours per day 303 days per year, consumes 1818 gallons of fuel per year. The annual cost of this idling is over $3,000 for fuel, plus more for additional preventative maintenance and engine overhauls. The DOE’s Office of Heavy-Duty Technologies estimates that the total cost of idling heavy-duty trucks in the US is $1.17 billion for fuel and $1 billion for extra maintenance.

Drivers idle their engines to power sleeper-compartment heaters and air conditioners, to power “hotel” accessories such as TVs, refrigerators, computers, tools, and fleet communications devices during nondriving operations, to avoid start-up problems in cold weather, to maintain air-system pressure, and simply as general practice during many delivery operations. Use of large diesel engines for idling is not only expensive and polluting; it also vibrates the cabin and is noisy, thereby disrupting driver sleep and creating a safety and performance concern.

An attractive auxiliary power unit that could replace the main engine is a diesel-fueled fuel cell. Two types of fuel cells could run on diesel fuel: a proton-exchange membrane fuel cell of the type being developed for cars, with a device to convert the diesel fuel to hydrogen, or a solid-oxide fuel cell that can operate directly on diesel fuel. As batteries and small alternative-fuel engines advance, they may also become appropriate. The use of fuel cells and other devices as auxiliary power units in long-haul trucks might lead to a migration of these clean, efficient devices to other trucks (and even cars), and also accelerate electrification of the truck’s drivetrain, steering, braking and other accessories— leading to even further efficiency and environmental benefits. It should also be pointed out that there is a need for APU devices in recreational vehicles (RVs), which spend a large amount of time in national parks and other wilderness locations. An analogy may be computers in cars, which initially were used to control emissions, but soon gained much wider applications.

Hybrid Vehicles

The stop-and-go drive cycle of many delivery trucks and buses is highly inefficient for both diesel and gasoline engines. Often these trucks are driven less than a hundred miles per day, and their average trip length may be only a few blocks. Not only is such a cycle very energy inefficient, it is also demanding on the engine and propulsion system.

Hybrid vehicles, in which a battery and electric motor are coupled with the existing internal combustion engine system, are far more efficient for these types of applications. Hybrid designs are beginning to be widely used in cars, light trucks, and buses; but they can also be used in intermediate-size trucks, perhaps with even greater benefit . Hybrid trucks are attractive in stop-and-go applications for a variety of reasons. One benefit is elimination of many engine starts. The vehicle could start with a battery, with the diesel engine turned on only when the vehicle’s computer determines that extra power is necessary; or, in other hybrid configurations, the engine turns on only to maintain the battery at a specified state of charge. A second benefit would be downsizing of the engine, whereby it operates near the most efficient load point at all times. The result is elimination of idling, elimination of hard accelerations that cause puffs of soot, and the ability to use regenerative braking to capture energy otherwise lost as heat during braking. Hybridization thus provides the potential for much greater energy efficiency and much lower emissions.

Conclusions and Recommendations

Diesel technology is evolving rapidly. It is not a mature technology. Earlier uncontrolled engines were highly polluting, noisy, and dirty; current engines are much cleaner and quieter, and future engines will be even cleaner. Improvements in energy efficiency and emissions are producing the “new” diesel—modern machines that are much less damaging to the environment than previous versions. How much cleaner, however, is still uncertain, and so are future health effects. What is known is that diesel engines will tend to produce higher NOx and particulate emissions than gasoline engines if they lack particulate filters, but better fuel economy and lower CO2 emissions. With filters, particulate emissions of all sizes can be dramatically reduced.

Opinions about the future role of diesel engines differ depending upon how one weights pollution and climate change. Many, especially in the US, believe air pollution from diesels is so serious that even new, cleaner diesel engines should not be used in light-duty vehicles and should be phased out of heavy- duty vehicles. In Europe, the prevailing view toward diesel is more benign, premised on a greater commitment to  greenhouse gas reduction. These differences are reflected in Europe’s more gentle treatment of light-duty diesel emissions.

greenhouse gas reduction. These differences are reflected in Europe’s more gentle treatment of light-duty diesel emissions.

However, characterizing the future of diesel engines as a trade-off between air pollution and greenhouse gases is a gross oversimplification. The environmental, health, and economic effects of using diesel engines are unclear and difficult to measure, and much of what we do know is based on data from older technology.

Diesel technology is here to stay for a very long time. It has compelling advantages that are difficult to replicate with other propulsion technologies and fuels. The massive R&D investment now being directed at mitigating the inherently high NOx and particulate emissions is bearing fruit, much as happened with gasoline engines. Diesel engines may not come as close to zero emissions as gasoline engines seem destined to, but it appears that they will eventually come close.

For now the focus of diesel improvements is on after-treatment devices, improved engine design and operation, low-sulfur fuels, and retrofit devices. At the same time, increasing emphasis will be placed on strategies for fundamentally cleaner and more efficient engines. These include hybrid electric drive trains, especially in medium-sized trucks used for deliveries, and fuel-cell auxiliary power units for long-haul heavy-duty trucks. Over time, hybrid electric and fuel-cell electric drive trains are likely to migrate to other truck types and other applications.

The challenge for public policy is to acknowledge but not be paralyzed by uncertainties—about health effects, climate change, and cost and performance of future technologies. Simplistic policies banning diesel or forcing particular technologies are inappropriate. Given the dramatic progress being made in reducing emissions, and the late start in doing so, polices aimed at mitigating the downsides of diesel engines are clearly desirable. These initiatives might include inspection and maintenance of vehicles, combined with random on-road testing— though difficulties with gasoline vehicle inspection and maintenance programs give pause. A less controversial and probably cheaper approach would be incentive funding. New Hampshire is considering economic incentives such as truck registration fees based on engine type and estimated emissions. Vehicle retirement programs should also be considered in cases where it is not economical to repair or retrofit a vehicle.

Public action and funding appear most justified for the following purposes and applications:

- Accelerated replacement of older polluting diesel transit and school Transit operators have limited funds, the bus market is small, and manufacturer commitment to this market segment is weak. Importantly, those exposed tend to be the most vulnerable (they are young, old, or poor).

- Public R&D funds to leverage industry investments in key technology areas and to support basic R&D at universities and other independent research centers.

- Incentives to buyers of next generation clean technologies, including fuel cell auxiliary power units and hybrid diesel-electric trucks.

Regulatory reform is also needed to reflect the mixed energy and environmental impacts of diesel engines, and the rapid progress being made with emission reduction. As previously noted, California and the US have adopted new particulate and NOx standards that are so stringent that they could eliminate the use of diesel in light-duty vehicles. This seems problematic.

It is important to note that light-duty emission standards were structured for gasoline cars. They are not based on a scientific formula; rather, they are based in part on how much reduction is needed to bring polluted areas into compliance with air quality standards and in part on determinations of what is deemed economically viable. For instance, standards for CO and HC have been more aggressively tightened than for NOx over the years in large part because it was judged easier and cheaper to accomplish. To maintain the spirit of the rules and goals, but recognizing diesel’s superior efficiency (and lower CO2 emissions), it would seem appropriate to explore ways of making the standards more flexible. This should not be done in a way that compromises air quality, but that provides more options for companies to expand their suite of products. And perhaps some means could be created to link the Corporate Average Fuel Economy (CAFE) program with emissions regulations. The ultimate goal should be design of a regulatory approach that allows manufactures to supply a mix of vehicles, fuels, and technologies that attain social goals at less overall cost.

Further Readings

Alan C. Lloyd and Thomas A. Cackette, “Critical Review, Diesel Engines: Environmental Impact and Control,” Journal of the Air & Waste Management Association, vol. 51, 2001.

Candace Morey and Jason Mark. Diesel Passenger Vehicles—Can They Meet Air Quality Needs and Climate Change Goals? Society of Automotive Engineers, Paper 2000-01-1599. 2000.

Kathleen Nauss, “Diesel Exhaust: A Critical Analysis of Emissions, Exposure, and Health Effects,” Summary of a Health Effects Institute (HEI) Special Report. HEI Diesel Working Group. 1997.

Renee Robins. The Future of Diesel: Scientific Issues, 2000 Air Pollution Symposium Summary. Massachusetts Institute of Technology, Energy Laboratory Publication No. 00-007 2000.

Michael Walsh, Global Trends in Diesel Emissions Regulation—A 2001 Update. Society of Automotive Engineers, Paper 2001-01-0183. (2001).